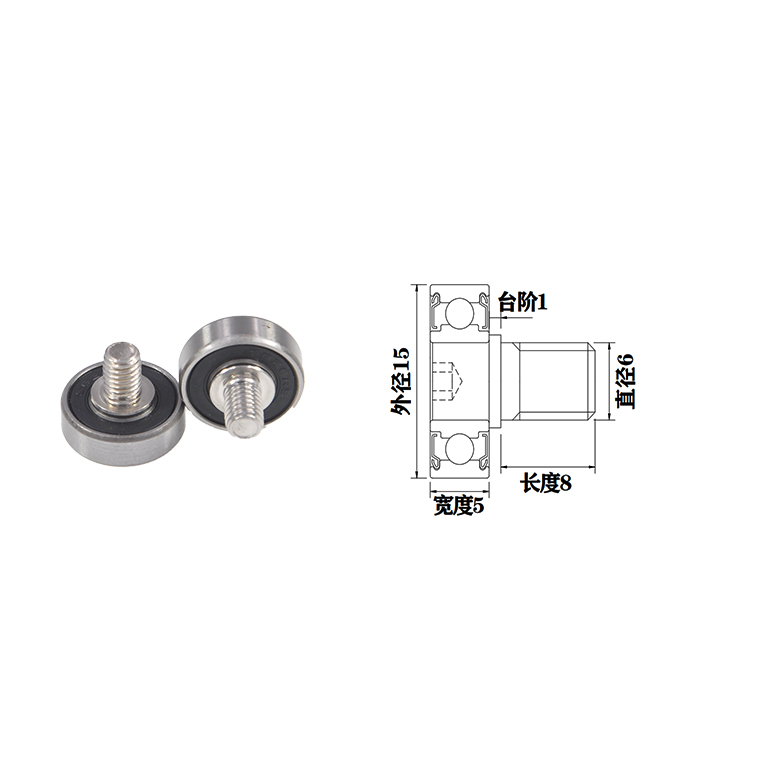

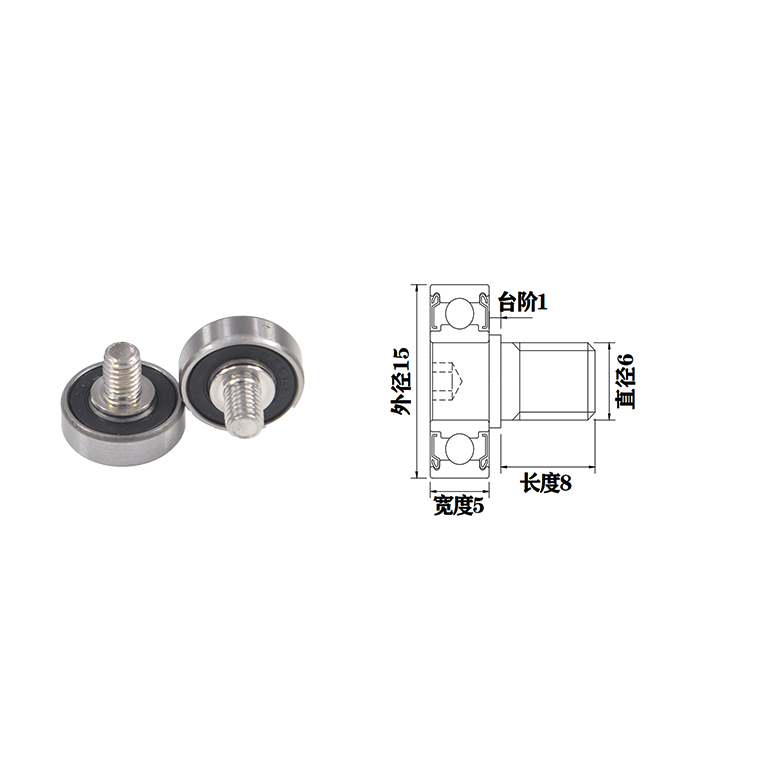

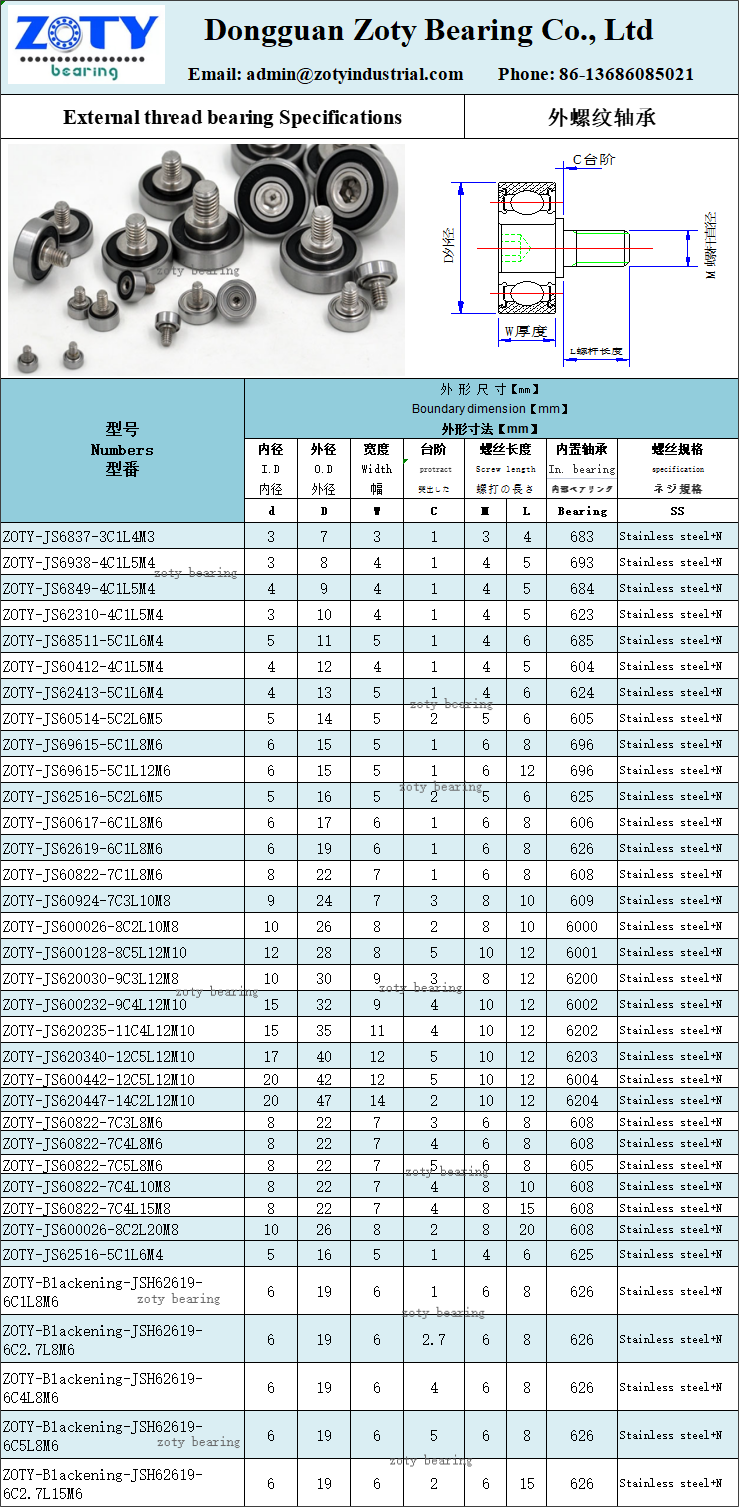

| Product Name | JS69615-5C1L8M6 M6x15x5mm Bearing Pulley With External Thread Screw |

| Brand | Neutral/ No brand |

| Model No | JS69615-5C1L8M6 |

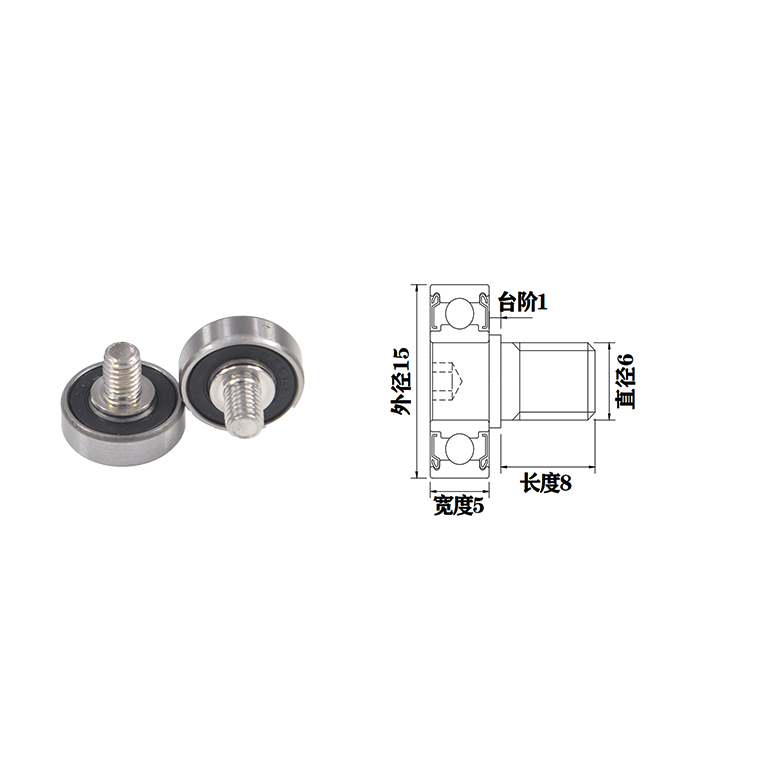

| Sizes(mm) | 696-2RS 6x15x5mm bearing |

| Material | Chrome steel bearing with 304 stainless steel screw bolt |

| Sealed Type | 2RS rubber seals/ ZZ metal shields/Open |

| Precision | P0, P5, P6/ ABEC-1, ABEC-3, ABEC-5, ABEC-7 |

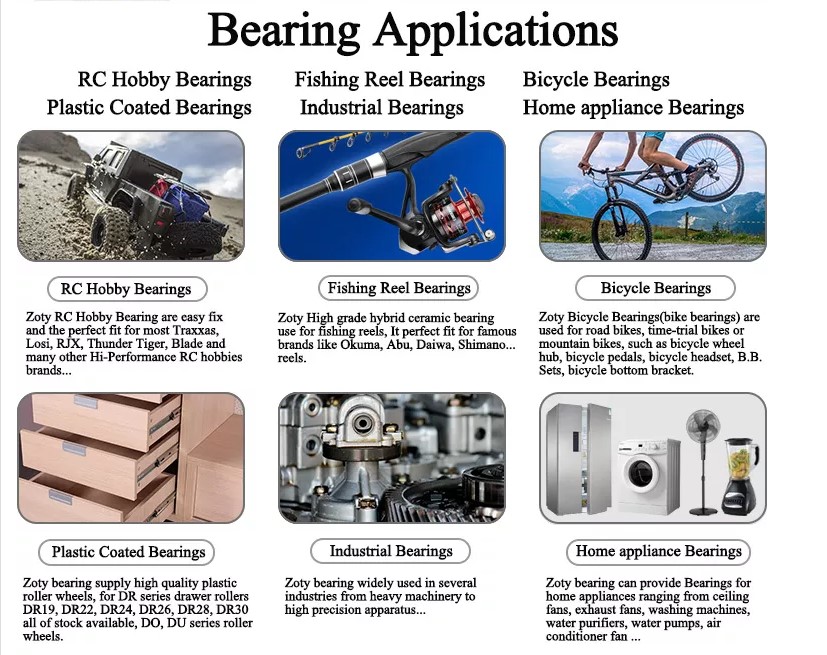

| Used | JS69615-5C1L8M6 M6x15x5mm Bearing Pulley With External Thread Screw, display rack...cabinet, furniture, sliding doors, windows |

| Packing | 200pcs/ Poly-bag |

| Shipping Method | By Air, Sea, Train, Truck, or other DDP Service |

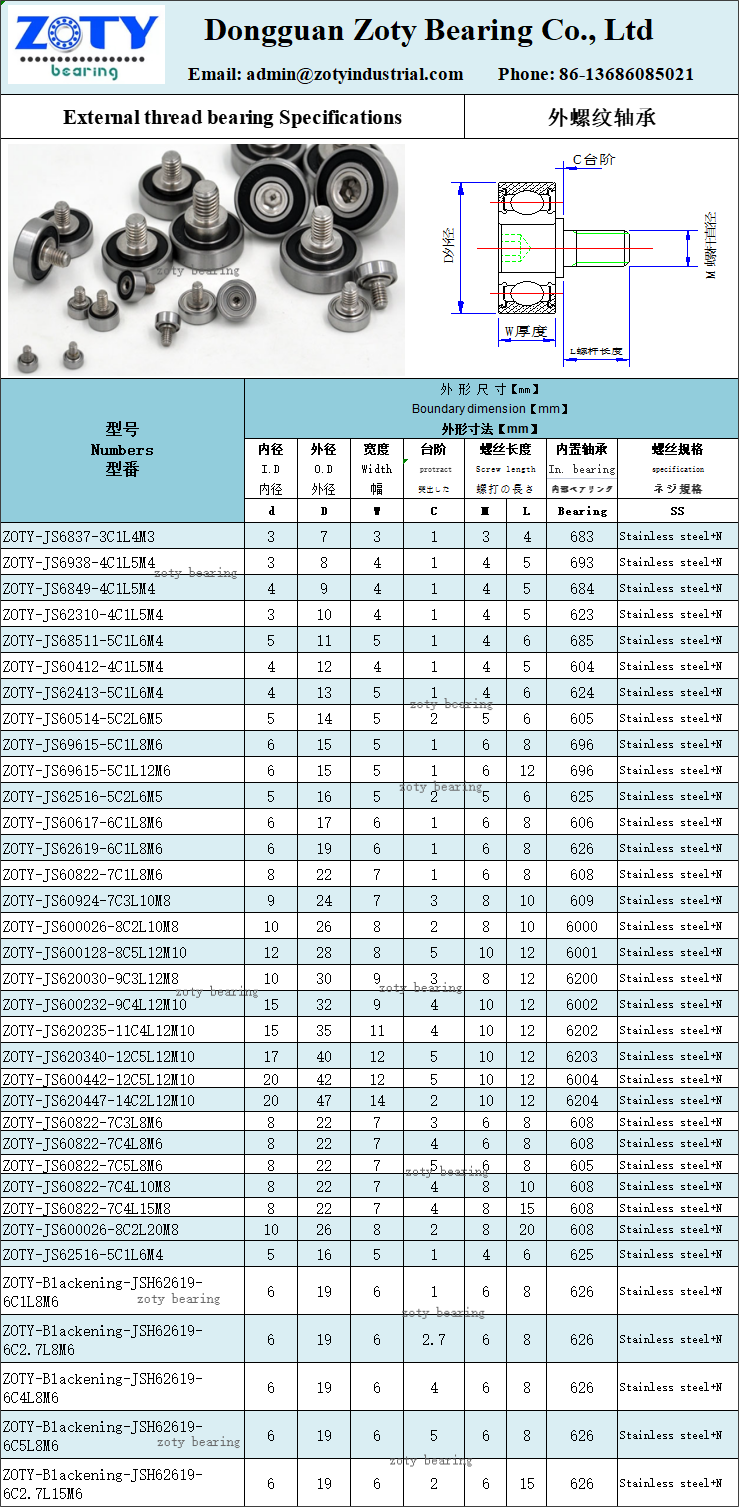

JS69615-5C1L8M6 M6x15x5mm Bearing Pulley With External Thread Screw

696-2RS rubber sealed single row deep groove ball bearings with M6 screw, outer diameter 15mm, width 5mm, SUS304 stainless steel screw threaded, the thread bearing made of chrome steel material bearing with 304 stainless steel screw, rustproof and high load capacity. long working life, rubber covered ball bearing, durstproof, waterproof.

Widely use for display stand, Display rack, Vending machines... tools. Samples can supply for test if needed, small order are welcome. accept cutomised order, please send your drawing.

Our bearing engineers and designers can tackle virtually any custom bearing project including:

Custom ball bearings Custom stainless steel pulley wheel

Custom bushings Custom plastic roller wheel

Custom pillow blocks or flanges Custom linear bearings

Custom rod ends Custom thrust bearings

Changed dimensions and / or tolerances

Extended inner ring

Extended outer ring

Modified/tapered bore

Modified outer ring

Deviating/narrow bore tolerances

Deviating/narrow outer diameter tolerances

Deviating/restricted radial play

What are the benefits of custom bearings? What advantages do they give engineers and the companies for which they work?

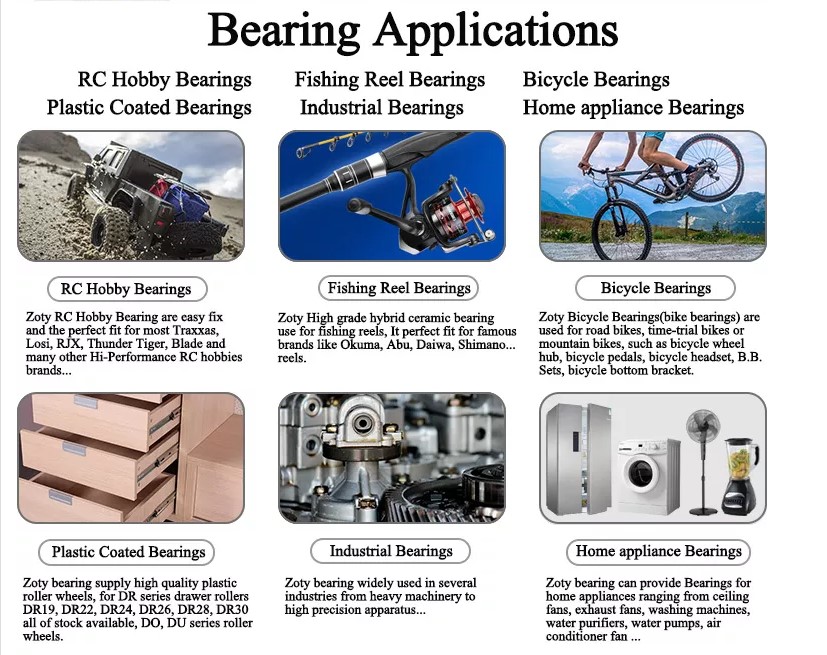

Custom bearings let engineers design and use components tailor-made for their specific applications. Such bearings can have longer working lives or better resist corrosion, thanks to bearing material chosen to resist contaminants in an application’s working environment. This reduces replacement and maintenance costs. Custom bearings can be produced with greater load ratings than ‘standard’ selections. They can also be made smaller or lighter to make installation easier. And from a market perspective, they can capture aftermarket replacement business for the OEM.